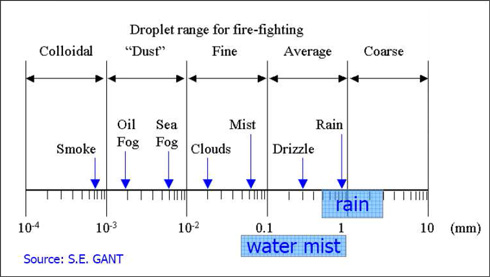

Water Mist is defined within NFPA 750 as a water spray where 99% of the water produced is distributed by droplets that are smaller than 1000 microns in diameter at the required design pressure at the water mist discharge nozzle.

We’re experts in the design, installation & servicing of all types of water mist systems.

Systems are typically categorised into high and low pressure. High pressure systems are defined as those which will operate at pressures greater than 35 bar, but typically from 70 – 130 bar. Low pressure systems typically operate at pressures up to 12 bar.

Both system types can be provided as either wet pipe or deluge systems. Wet pipe systems will operate in the same way as a standard sprinkler system utilising nozzles that incorporate a frangible bulb element that will rupture and activate the system once the pre-determined temperature is reached. Deluge or dry pipe systems will typically operate from electronic detection systems which will then provide a signal to activate a cylinder valve or pump.

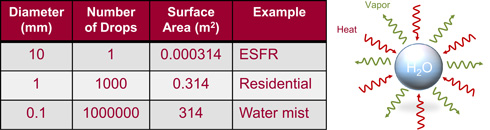

The two main mechanisms employed by water mist for the control and extinguishment of fire are by vapour generation and surface cooling of the fire itself. When water vaporises it displaces air to over 1,600 times its original volume, thereby depleting Oxygen within the protected enclosure or local to the fire. As the water mist droplets are smaller in diameter than conventional sprinkler droplets they present a greater surface area for cooling the surface of the fire which therefore absorbs heat faster. The table below demonstrates the surface area available in relation to droplet size.

Consequently, water mist systems will extinguish a fire by improved cooling and blockage of radiant heat but with reduced water demand when compared to traditional sprinkler systems.

High Pressure

High pressure water mist systems are supplied either as cylinder systems or with a high pressure pump assembly and storage tank. The type of system supplied will be dictated by the coverage area required and the required run time of the agent.

High pressure systems are suitable for use on either Class A or Class B fires although the mechanism for the control and extinguishment of the fire will vary depending on the risk.

Tube and fittings utilised on high pressure systems are 316L stainless steel.

Low Pressure

Low pressure water mist systems are supplied with a pump assembly and break tank. As with high pressure systems, low pressure systems can be utilised on both Class A and Class B fires but are typically employed as an alternative to conventional sprinkler systems where water storage is difficult.

As less water is used when compared to standard sprinkler systems, the low pressure mist distribution pipework is also of a smaller bore than sprinkler pipework, thereby facilitating an easier installation. All tube and fittings employed on a low pressure mist system are corrosion resistant in nature, such as galvanised or stainless steel.

The ULF Aquamist nozzles AM27 and AM29 are closed head nozzles which are used on wet pipe systems. Both have successfully performed in full scale fire testing by Factory Mutual as described in the Class 5560 protocol. The open deluge AM4 nozzle is also both UL and FM approved.